You are aware of the significance of wearing a hard helmet at all times, whether you are employed in an office, a factory, or a construction site. What distinguishes hard hats and hard hats from one another among the several types of head protection available on the market? In this article, we’ll look at how hard hats and hard helmets compare and contrast. You should be able to choose the best sort of helmet with the aid of the information provided.

While choosing a helmet or other form of head protection, take into account the jobs you will be undertaking. When working in an industrial or construction situation, a hard hat must be worn at all times. In other situations, a hard hat may be all that is needed. Get a hard hat that fits you well and is weatherproof where you work.

Clearly describe the hard hat.

A hard hat is a type of protective headgear worn by workers in fields where concussions or other head injuries from falling objects or unintentional accidents with other objects could occur. Hard hats protect not the object to which they are attached from potential impact pressures, but rather the user from abrasions, cuts, and scratches. They frequently contain a visor and are composed of soft materials like cotton or foam to protect the wearer’s face from flying debris. Hard hats must typically be used in conjunction with other PPE, like hard helmets or safety glasses.

Hard hats come in a variety of styles, each with a unique set of characteristics and a varied pricing range. Although not all hard hats include reflective strips or built-in lights, those that do increase the wearer’s visibility in low light. Furthermore, chin strapped bump helmets are available. The hard hat won’t come off as readily as a result.

What precisely does the hard hat do?

Due to the protection they offer against grazes, scratches, and bruises, hard hats are frequently used in the industrial and construction sectors. Workers in the food service industry and other places where head injuries from falling objects could occur wear them. Hard hats are often composed of high-density polyethylene or similar type of hard plastic to provide a snug fit over the top of the head.

Hard hats are not meant to take the place of hard hats, despite being safer than wearing no head protection at all. Workers are required to wear hard helmets in places like construction sites where severe head injuries are conceivable. Hard hats are only used in situations where the dangers are thought to be limited.

Hard hat vs. Hard Hat

When it comes to securing their noggins, consumers have a number of alternatives. Hard hats and hard hats, however, are currently among the most popular options for head protection. The two styles of headgear are compared below, with specific focus placed on the main distinctions: Bump hats are made to shield the head against bumps and falls with minimal impact. Hard hats, on the other hand, are designed to withstand more powerful impacts, such as those caused by items falling from the sky. When manufacturing hard hats, thin, lightweight materials like plastic or foam are frequently used. Yet, tougher materials like polycarbonate or fibreglass are frequently employed when making hard helmets.

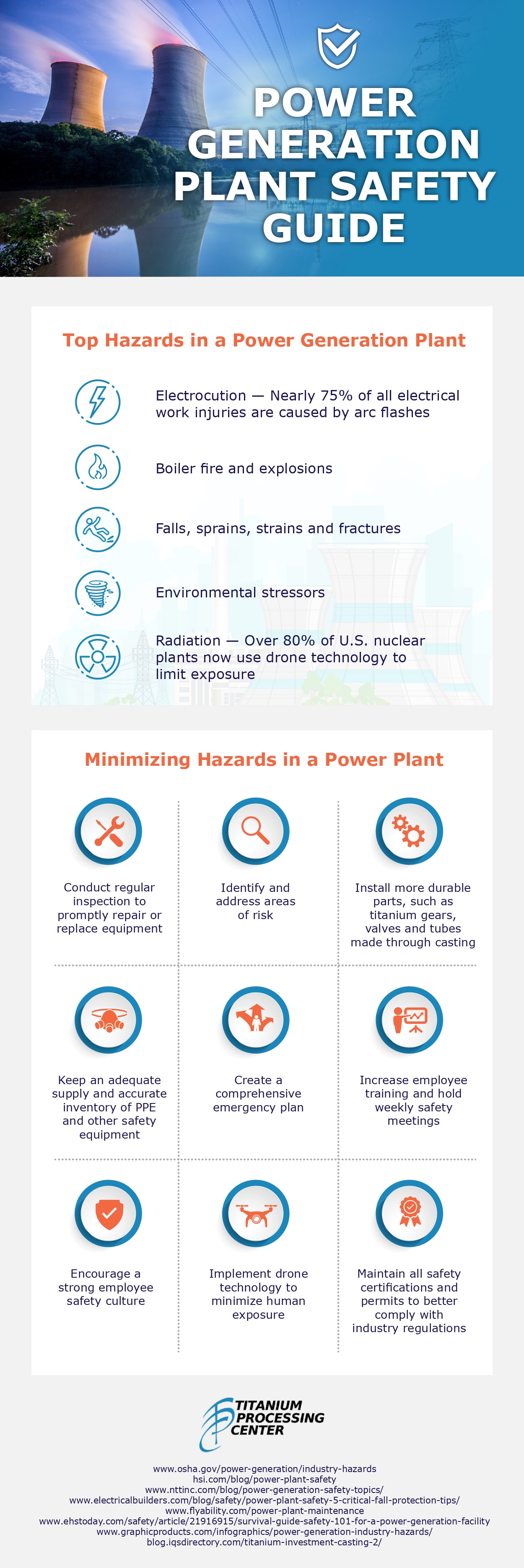

Hard hats are just on example of PPE that an industry might require. To learn more on how those in the energy industry stay safe on power plants, please see the information below.

Provided by Titanium Processing Center – a titanium company