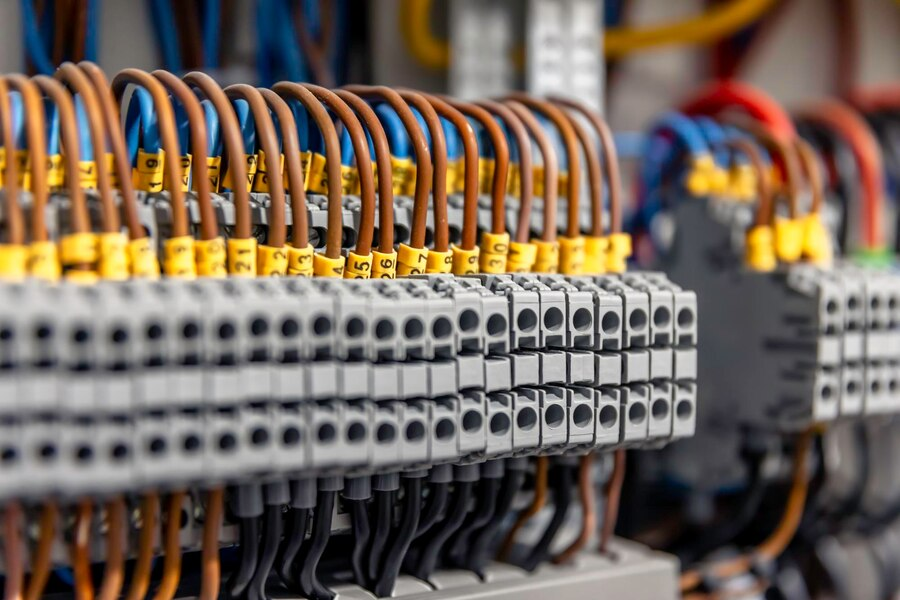

In the intricate world of custom wholesale wire harness assembly, achieving pristine surface preparation is not just a preference but a necessity. Surface preparation sandblasting emerges as a pivotal process, ensuring that every wire harness meets stringent quality standards and performs reliably in diverse applications.

Understanding Surface Preparation Sandblasting

Surface Preparation Sandblasting, often referred to simply as sandblasting, is a technique used to clean, polish, or etch surfaces using abrasive materials propelled at high speeds. This method is highly effective in removing rust, old coatings, contaminants, and preparing surfaces for subsequent treatments like painting or coating. In the context of custom wholesale wire harness assembly, where precision and reliability are paramount, surface preparation sandblasting plays a crucial role in enhancing both the aesthetic appeal and functional integrity of wire harnesses.

Enhancing Durability and Longevity

One of the primary advantages of surface preparation sandblasting in wire harness assembly is its ability to significantly enhance durability and longevity. By removing surface contaminants and imperfections, the sandblasting process ensures that wire harnesses are free from corrosion-inducing elements. This is particularly critical in industries where wire harnesses are subjected to harsh environmental conditions or rigorous operational demands.

Optimizing Adhesion for Coatings

In many applications, wire harnesses require protective coatings to resist moisture, chemicals, or abrasion. Surface preparation sandblasting provides an ideal substrate by creating a clean and roughened surface that promotes superior adhesion of coatings. Whether it’s epoxy, polyurethane, or other specialized coatings, the effectiveness of these applications hinges on the quality of surface preparation achieved through sandblasting.

Precision Cleaning for Consistency

Consistency is key in custom wholesale wire harness assembly. Sandblasting ensures uniformity by precisely removing contaminants and irregularities from surfaces. This level of precision is essential not only for aesthetic purposes but also for maintaining electrical conductivity and ensuring that connectors and terminals fit snugly without interference.

Meeting Stringent Quality Standards

In industries such as automotive, aerospace, and electronics, adherence to stringent quality standards is non-negotiable. Surface preparation sandblasting aids in meeting these standards by preparing wire harness surfaces to exact specifications. Companies like Casco Manufacturing are cable assembly manufacturers that rely on such meticulous processes to ensure the highest level of quality in their products. This proactive approach minimizes defects, improves overall product quality, and reduces the likelihood of premature failures due to inadequate surface preparation.

Improving Efficiency and Cost-Effectiveness

Efficiency and cost-effectiveness are always top priorities in manufacturing processes. Surface preparation sandblasting streamlines production by reducing the need for manual cleaning and prepping of wire harness components. This not only saves time but also optimizes resource utilization, ultimately contributing to lower production costs and improved profitability for custom wholesale wire harness manufacturers.

Ensuring Safety and Compliance

Safety considerations cannot be overlooked in any manufacturing environment. Surface preparation sandblasting, when performed with appropriate equipment and safety protocols, ensures a controlled and safe process. This mitigates risks associated with handling hazardous materials and protects workers from potential health hazards, thereby fostering a safer workplace environment.

Conclusion

Surface preparation sandblasting stands as a cornerstone of excellence in custom wholesale wire harness assembly. From improving durability and efficiency to ensuring safety and compliance with industry standards, sandblasting plays a pivotal role in elevating the quality and reliability of wire harnesses. As industries continue to demand higher standards and innovation, the importance of surface preparation sandblasting in achieving these goals cannot be overstated. It is not just a process but a catalyst for excellence in every wire harness that powers modern technologies and applications.